A product’s journey from the warehouse to the customer hinges on one crucial detail—its packaging. Packaging is about choosing the right box with the perfect dimensions. Why is this so important? Choosing the wrong size can drive shipping costs, compromise product safety, and ultimately leave customers dissatisfied. Imagine paying extra to ship a box filled mostly with air or dealing with the frustration of damaged products because the fit was too tight. Whether you’re a business owner preparing to ship products or someone figuring out the right box for storage, knowing how to measure and select the correct packaging box dimensions is essential.

In this guide, we’ll discuss the steps to measuring a box, the significance of accurate package measurements, and the factors that influence the choice of box size. By the end, you’ll know exactly how to determine the dimensions of a packaging box for various needs.

Why Are Box Dimensions Important?

In packaging, box dimensions significantly impact how smoothly your product travels from the warehouse to the customer. If a box is the wrong size, it can lead to higher shipping expenses due to wasted space, excess packing materials, and even product damage. For businesses, these small inefficiencies can accumulate and lead to substantial costs in the long run.

Shipping companies rely on box measurements to calculate shipping rates, and retailers depend on them to efficiently use warehouse space. For example, if your boxes are larger than necessary, you might pay for more shipping volume than you need, a common issue in cosmetic shipping. Similarly, a box that’s too small may not offer enough protection, leading to damaged goods and unhappy customers.

Accurate cardboard box dimensions ensure the following:

- Protection: A properly sized box helps prevent product damage during transit by minimizing movement inside the box.

- Cost Efficiency: Shipping rates are often based on dimensional weight, so smaller boxes save on costs.

- Customer Experience: Well-fitted boxes improve the unboxing experience and give a professional impression.

- Sustainability: Larger boxes require more packaging material, leading to waste. Reducing unnecessary materials benefits both the environment and your bottom line.

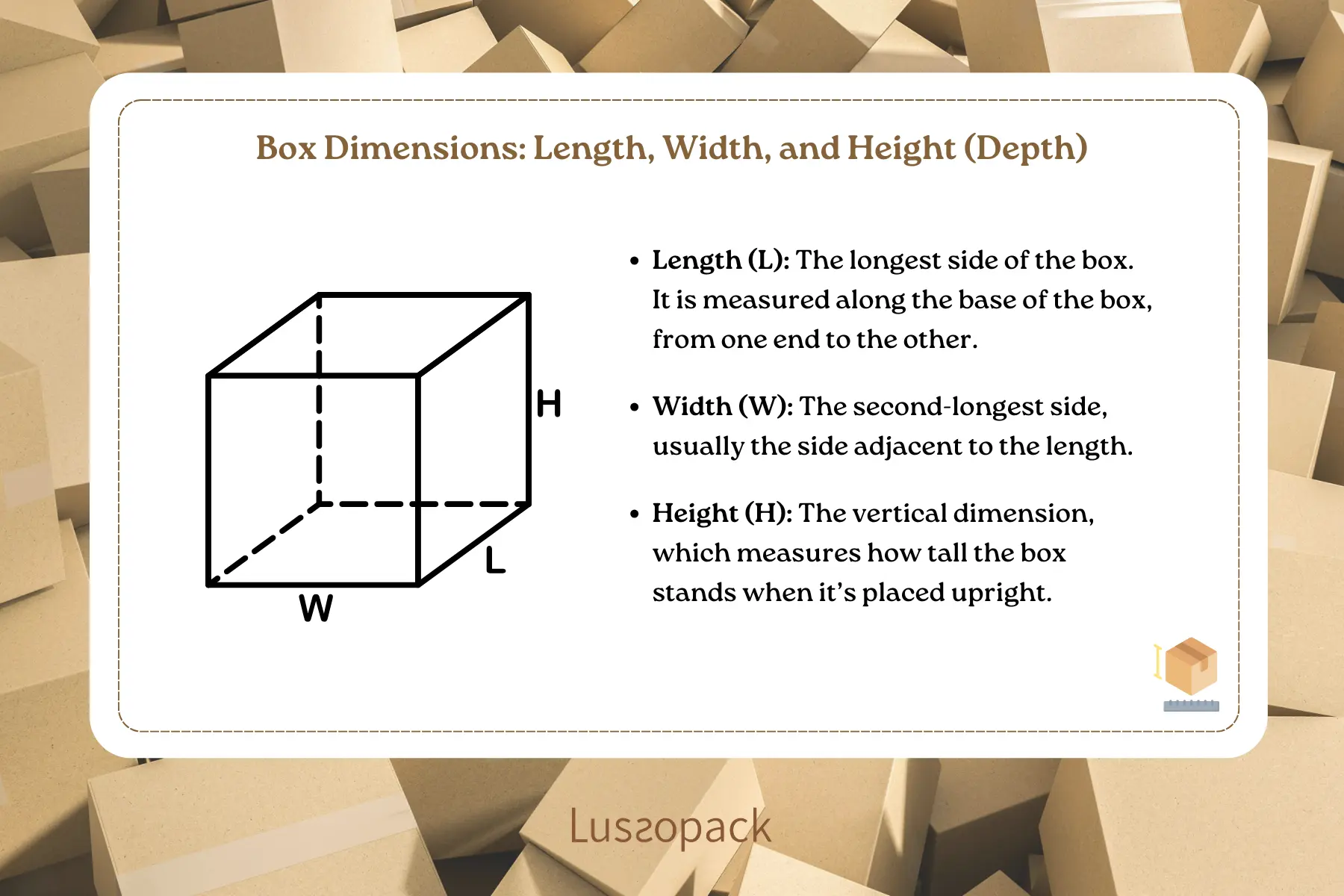

The Three Key Dimensions: Length, Width, and Height

When discussing the dimensions of a box, the three primary measurements you need to focus on are Length, Width, and Height (Depth). These may sound simple, but knowing how to measure them correctly is important, especially when you’re working with bulk orders or multiple products. So what is length, width, and height of a box? Let’s break down what each dimension refers to in practical terms:

- Length (L): This is the longest side of the box. It is measured along the base of the box, from one end to the other.

- Width (W): The second-longest side, usually the side adjacent to the length.

- Height (H) (Depth): The vertical dimension, which measures how tall the box stands when it’s placed upright.

It’s essential to understand the order in which these dimensions are presented: Length x Width x Height (L x W x H). This order is an industry-standard. Mixing up these dimensions can result in improper packaging design, inaccurate shipping cost estimates, or, in the worst case, a product that doesn’t fit the box properly.

How to Measure Dimensions of a Box

When measuring a box, you need to consider both internal and external measurements, as they serve different purposes that are vital for E-Commerce businesses. Internal measurements ensure that your products will fit inside the box, while external measurements are used to calculate shipping costs and plan storage.

Step 1: Gather the Right Tools

To start, you’ll need a reliable measuring tool. A flexible tape measure works best for larger boxes, while a rigid ruler or digital calipers may be more useful for smaller, precise measurements. For example, if you’re working with fragile items like electronics or collectibles, packaging box dimensions must be precise to prevent damage.

Step 2: Measure the Internal Dimensions

The internal dimensions are what determine whether your product will fit inside the box comfortably. These measurements are essential when ensuring a snug fit or when products need additional padding or protective materials.

- Length: Measure the longest inside dimension of the base of the box.

- Width: Measure the shorter side of the base.

- Height (Depth): Measure from the bottom inside of the box to the top edge.

Recording these internal box packaging dimensions ensures your products will fit securely and won’t shift during transit.

Step 3: Measure the External Dimensions

External dimensions are important for logistics, shipping, and stacking purposes. When shipping, these package measurements help calculate costs based on dimensional weight.

- Measure the outside of the box for length, width, and height.

- Always account for the thickness of the box material when calculating external dimensions, as thicker materials will increase the overall size.

Understanding both internal and external dimensions gives you a comprehensive view of the box’s usability for storage, shipping, and product protection.

Dimensional Weight: A Key Shipping Factor

In shipping, one of the most important factors that determines cost is dimensional weight, often referred to as “volumetric weight.” This is because shipping companies charge based on the space a package takes up in a truck or airplane, not just its physical weight. If you’re shipping large but lightweight items, you might be surprised by how much more you’ll be charged due to the size of the box.

How to Calculate Dimensions of a Box for Shipping

To calculate the dimensional weight of your package, follow these steps:

- Multiply the length, width, and height of the package (using external dimensions).

- Divide this number by the carrier’s dimensional weight divisor. For example, major carriers like UPS and FedEx use a divisor of 139 for domestic shipments and 5000 for international shipments (measured in cubic centimeters).

Let’s consider an example where you have a box with dimensions of 18 x 12 x 10 inches:

- 18 x 12 x 10 = 2,160 cubic inches

- 2,160 ÷ 139 = 15.5 lbs (dimensional weight)

n this case, even if your package only weighs 10 pounds, you’ll be charged 15.5 pounds based on the space it takes up in the shipping vehicle. This is why having a clear understanding of packaging dimensions is vital when calculating shipping costs.

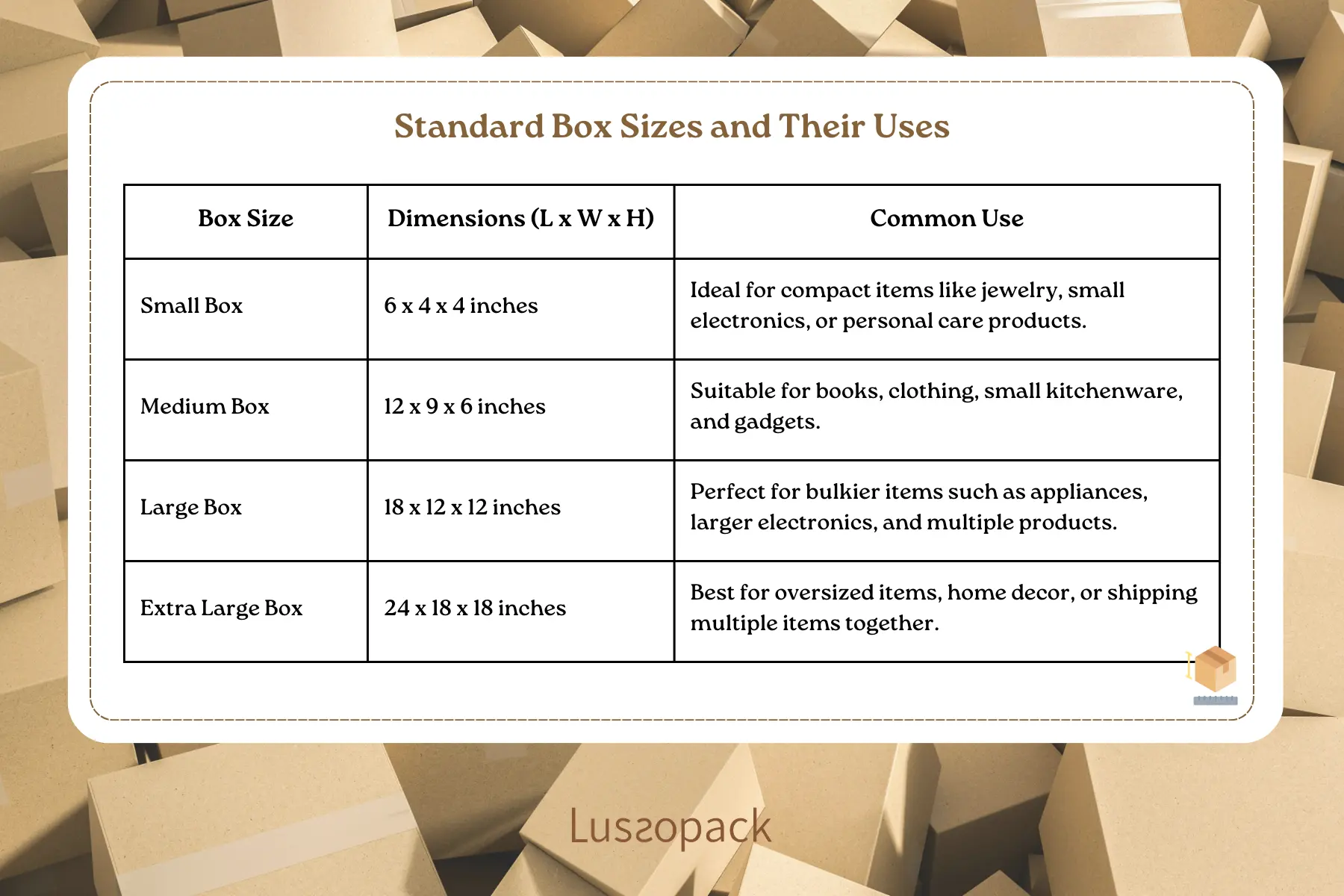

Standard Box Sizes and Their Uses

For shipping and packaging, using standard box sizes provides a fast and efficient option for a wide range of products. These commonly available sizes are typically more affordable and help simplify your packaging and shipping workflow.

Here are a few of the most common shipping box sizes and their uses:

Using standard package sizes allows you to simplify your operations by reducing the need for custom packaging, which can be time-consuming and expensive. However, if you have specific product requirements or need to make a unique impression, custom-sized packaging may be necessary.

Custom-Size Boxes for Shipping

While standard shipping box sizes work well for most situations, there are times when custom-size boxes for shipping are the best option. Custom boxes can be designed to fit the exact dimensions of your product, providing a snug fit and reducing the need for excess filler material.

Custom boxes are especially useful for:

- Irregularly shaped items that don’t fit well in standard box dimensions.

- Luxury products where branding and presentation are prioritized.

- Fragile or high-value items that require additional protection during shipping.

Though custom boxes are more expensive than standard ones, they offer greater flexibility and can present your brand image through tailored packaging.

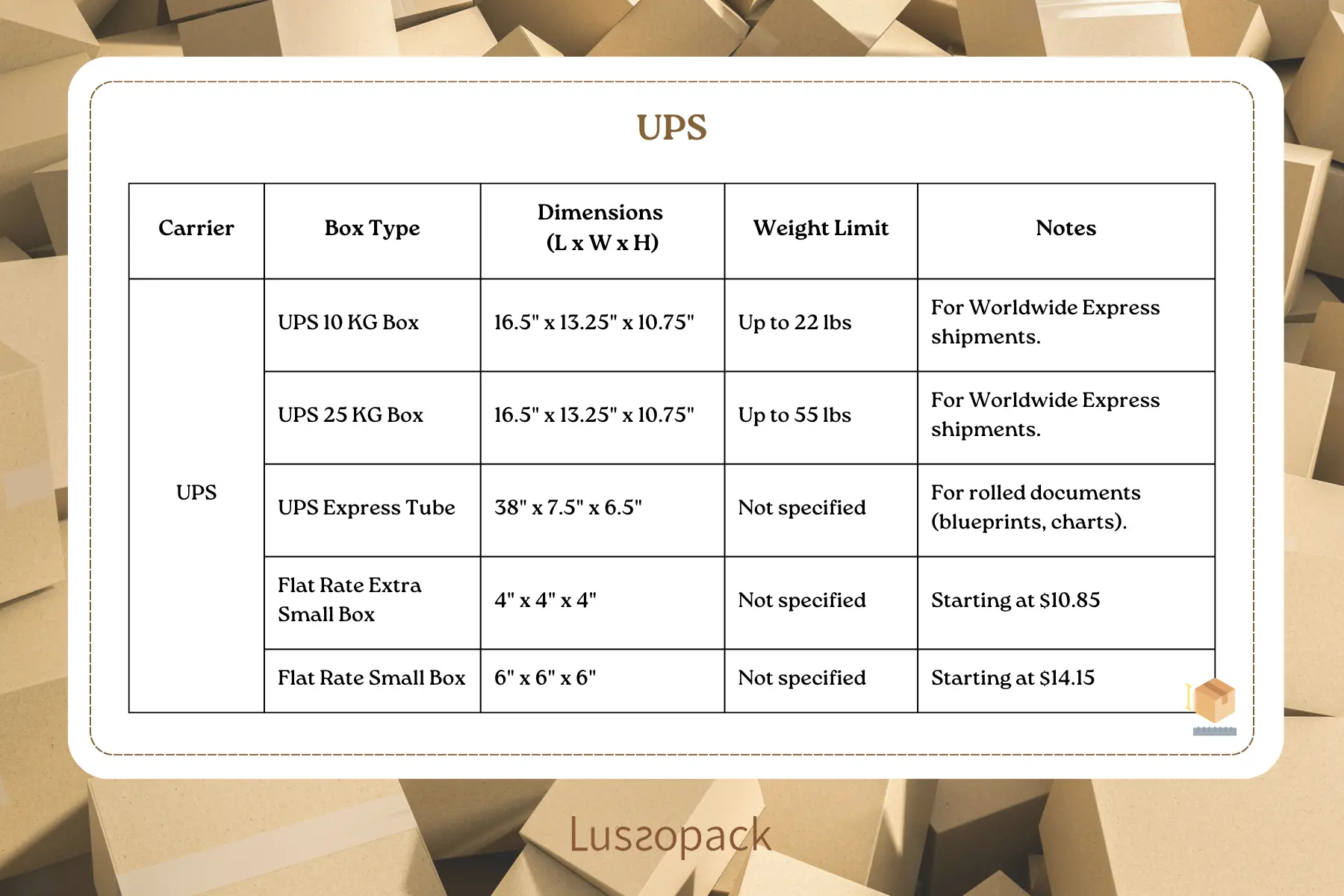

Carrier-Specific Requirements of Box Dimensions

Shipping carriers often have strict guidelines for the maximum size and weight of packages they will accept, and exceeding these limits can lead to extra fees or the refusal of your shipment. These regulations typically relate to dimensional weight, which takes both the size and the weight of the package into account. For example, larger boxes that are lightweight may incur higher shipping charges due to the space they occupy in transit.

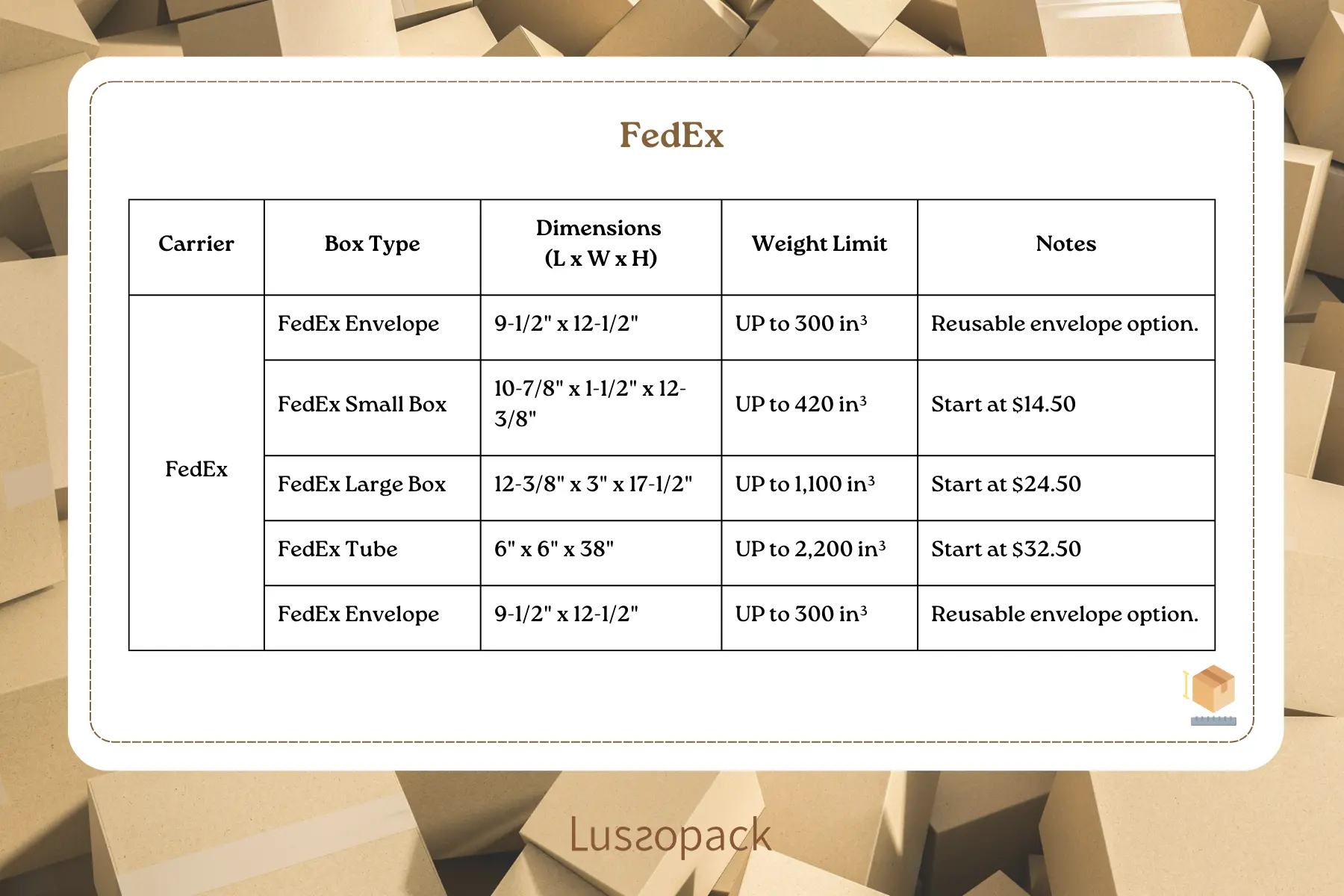

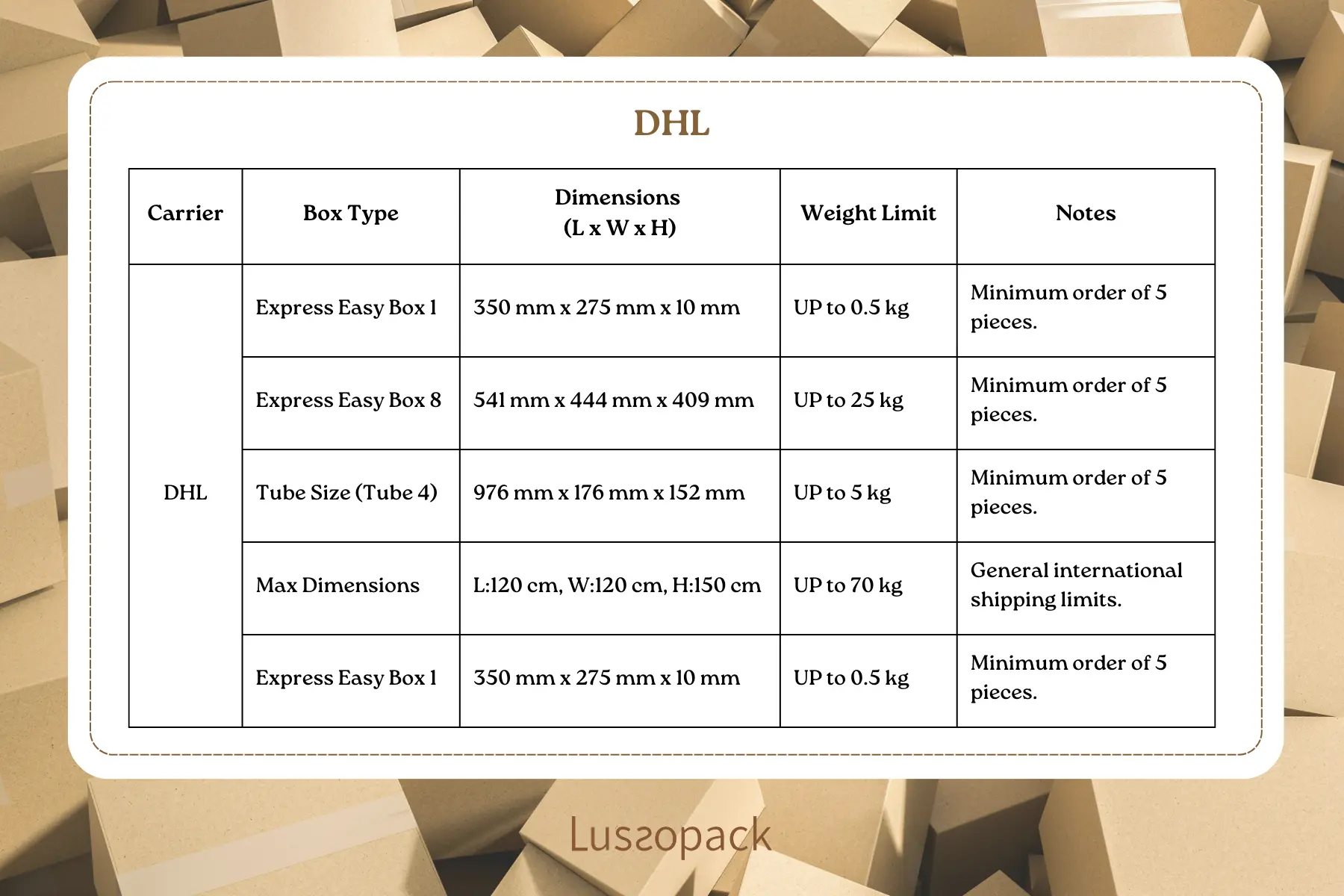

Here are examples of the specific legal and carrier requirements set by UPS, FedEx, and DHI.

You can find all the essential details through these links:

You can find all the essential details through these links:

You can find all the essential details through these links:

Common Mistakes in Measuring Box Dimensions

While measuring box dimensions may seem straightforward, several common mistakes can lead to shipping issues, increased costs, or customer dissatisfaction:

- Not Accounting for Box Thickness: When measuring the external dimensions of a box, don’t forget to account for the thickness of the cardboard. This can impact the overall size, and a thick box may take up more space than anticipated.

- Mixing Up Length, Width, and Height (Depth): Always measure and list dimensions in the correct order (Length x Width x Height). Confusing these dimensions can result in errors when ordering or shipping boxes.

- Ignoring Internal Space for Padding: If your product requires padding or protective materials, make sure to leave enough space for them. Failing to account for this could result in damaged goods during transit.

From choosing the appropriate box size to understanding dimensional weight and carrier guidelines, this guide has provided you with the essential knowledge to navigate the complexities of packaging logistics. By carefully measuring both internal and external dimensions and aligning with the specific needs of your products and carriers, you can avoid common mistakes and set your business up for success.

With companies like Lussopack, we have expertise in luxury packaging solutions and excel in this arena by offering customized packaging projects that cater to diverse industries ranging from fashion to wine and spirits. Lussopack’s customized packaging solutions offer a wide range of industries, from automotive components and amulets to coins and high-fashion items. Each project is designed to reflect the distinctive identity and high standards of the brands they serve, ensuring that every packaging solution is tailored to elevate the product’s presentation. Lussopack’s commitment to ‘Made in Thailand’ craftsmanship ensures high-quality, durable packaging tailored to meet the specific needs of each client. For businesses looking to elevate their packaging standards and make a lasting impression on the market, Lussopack is a prominent choice.

For more detailed insights into our offerings and services, reach out to us for valuable information and inspiration to meet your packaging needs.