Packaging prices have shifted a lot over the past few years. Materials cost more than they used to, eco options are no longer “nice to have” for many brands, and customers notice the small details, like the feel of the paper, the fit of an insert, and how the box opens.

Now that we’re in 2026, budgeting for packaging comes with more moving parts than ever. Whether you’re choosing simple cartons for everyday orders or planning a fully bespoke rigid box for a hero product, it helps to know what’s actually driving the price, and how to estimate costs before you commit.

In this guide, we’ll break down what impacts packaging pricing across entry-level, mid-range, and premium options, including sustainable choices. The goal is to help you make decisions that fit your product, your budget, and the kind of experience you want customers to have when they open the box.

The Factors That Influence Packaging Costs

Packaging cost is influenced by several variables. Knowing these factors will help you evaluate suppliers more accurately and tailor packaging to fit your brand and budget.

- Materials

Different packaging materials have different costs. Rigid boxes are more expensive than folding cartons. Recycled kraft paper is cheaper than premium textured paper. Plastic-free and biodegradable options can also shift costs.

- Finishes and Details

Elements like foil stamping, embossing, velvet linings, or magnetic closures raise the price. These are often used in luxury packaging to elevate the unboxing experience.

- Customization Level

Standard box templates are more affordable. But if you’re creating a custom structure, expect additional design and tooling fees.

- Production Volume

Packaging pricing improves with higher quantities. Small-batch orders (fewer than 500 units) are usually less cost-efficient.

- Sustainability

Sustainable materials can cost more upfront. Certifications (like FSC) or biodegradable coatings increase cost but align with long-term brand value.

- Packaging Design

The cost of packaging design should be factored in early, particularly for brands pursuing distinctive layouts or high-end finishes. The packaging design price can vary widely based on complexity, the number of revisions, and whether the work is handled in-house or outsourced to a specialized design team.

Average Cost Ranges by Packaging Type

While exact figures depend on the project, here are packaging cost examples to give a ballpark understanding. Whether you’re just starting out, developing packaging for watch brands, or building a premium luxury line, it’s important to understand what your investment will likely look like at each level.

Entry-Level Packaging

These solutions are budget-friendly and ideal for mass distribution or introductory product lines.

- Common formats: folding cartons, pillow boxes, lightweight mailers

- Materials: thin paperboard or recycled kraft paper

- Printing: basic digital or offset print, often with a matte or gloss finish

- Design: minimal customization, mostly standard die lines

- Cost range: x$0.30 to $1.50 per unit

This tier is especially well-suited for companies seeking affordable shipping boxes that still deliver visual appeal and a branded touch. It offers a smart entry point for businesses launching new products, testing markets, or managing limited budgets without compromising on presentation. Ideal applications include small accessories, entry-level jewelry collections, subscription kits, and promotional giveaways. If you’re wondering how much does packaging cost for a small business, this level often provides the most accessible and scalable solution—allowing brands to maintain quality while keeping costs tightly controlled.

Mid-Range Packaging

Perfect for boutique or artisan brands that want custom branding without luxury-level pricing.

- Common formats: rigid drawer boxes, magnetic flip boxes, or two-piece setups

- Materials: sturdy paperboard or chipboard with wrapped exteriors

- Enhancements: foil stamping, embossing, custom inserts like foam or molded pulp

- Printing: higher quality offset with color consistency and Pantone matching

- Cost range: $2.00 to $5.00 per unit

This category offers an ideal middle ground—delivering elevated aesthetics and tactile quality. It strikes a thoughtful balance between visual impact and budget, making it especially appealing for brands that want to make a strong impression without overextending on spend. The flexibility of design and materials in this range supports scalable production while maintaining a custom-branded feel. These packaging solutions are well-suited for mid-tier timepieces, fine costume jewelry, seasonal gift sets, and boutique retail collections.

Premium Packaging

At this level, packaging becomes a true extension of luxury branding.

- Formats: fully bespoke rigid boxes, fold-out display cases, boxes with embedded technology (like NFC tags or LED lighting)

- Materials: luxurious textured papers, velvet interiors, PU leather wraps, acrylic windows

- Features: multi-layer designs, magnetic closures, hinges, personalized inserts

- Printing: combination of specialty techniques—spot UV, blind embossing, soft-touch finishes

- Cost range: $6.00 to $20.00+ per unit

These are ideal for hero products such as engagement rings, luxury watches, high-value gifting, or special edition releases. Wondering “how much does packaging cost for a product” like a high-end watch? You’re likely in the upper range of this bracket.

Remember, how much does custom packaging cost will always depend on your volume, material choices, and the uniqueness of your design. Customization can transform a simple box into an immersive brand experience—but it comes at a premium.

The Hidden Costs Behind Packaging Production

Beyond the per-unit price, consider hidden or indirect packaging costs that can significantly affect your total investment.

- Tooling & Die-Cuts

If your box requires a custom shape or opening mechanism, you may need to invest in a die-cut mold. This is a one-time setup fee that varies based on complexity and size but can range from $200 to over $1,000. These are especially common for unique rigid boxes or multi-component designs.

- Sampling & Prototyping

Before full production, it’s standard to request a prototype or pre-production sample to confirm quality, color, texture, and structural integrity. These prototypes can cost anywhere from $100 to $300+, particularly if you require hand-assembled or fully finished samples. Multiple rounds of revisions may incur additional costs.

- Freight and Logistics

Packaging often involves bulk shipments. The larger and heavier your packaging, the more you’ll pay in freight. If you’re importing internationally, additional costs may include customs duties, tariffs, and clearance fees. A common question is how much does it cost to ship something internationally? For international packaging, shipping can range from $300 for small pallets to several thousand dollars depending on volume and destination. Also consider express shipping for tight timelines—this premium can double your logistics costs.

- Storage and Warehousing

If your facility can’t accommodate large shipments, you’ll need off-site warehousing. Warehousing fees include both rent and handling costs. Long-term storage also risks damage, so insurance is recommended. Seasonal businesses should also consider the cost of holding unsold stock between cycles.

- Handling, Assembly, and Fulfillment

If your packaging involves multiple parts (box, sleeve, ribbon, foam insert), you may incur additional labor costs to assemble each unit. This is especially true with hand-crafted boxes or multi-part sets.

Being aware of these factors is essential if you want to calculate the true packaging cost. Each hidden line item may seem small on its own but can add up significantly at scale.

The Cost of Sustainable and Eco-Friendly Packaging

Sustainability matters. But is eco-friendly packaging more expensive? In most cases, yes—at least upfront. Materials like recycled board, biodegradable lamination, or compostable trays are often pricier than conventional options. However, this cost is decreasing as green manufacturing becomes mainstream

- Short-Term Cost, Long-Term Value

Eco-packaging often pays for itself in the long run. Customers prefer brands with sustainable practices. And governments are beginning to mandate environmental standards, making early adoption smart. Integrating sustainability also enhances your brand image in the eyes of increasingly conscious consumers.

- Certifications and Materials

FSC-certified paper, soy-based inks, or plastic-free adhesives add slight premiums. These contribute to both product safety and brand responsibility. The sourcing, auditing, and verification process for these materials also requires more oversight, which is factored into the overall packaging cost.

If you’re wondering, “Is sustainable packaging more expensive?” the answer is yes, but it also delivers greater long-term value as previously discussed. Eco-friendly packaging strengthens brand reputation, meets growing consumer expectations, and aligns with broader global sustainability commitments.

How to Calculate Packaging Cost

Understanding how to calculate packaging cost is essential for forecasting budgets, setting product pricing, and optimizing your margins. While exact numbers vary by project, the following method will help you build a reliable estimate:

Step 1: Identify All Cost Elements

- Materials:b> Cost of paperboard, rigid board, plastic, or sustainable alternatives

- Printing & Finishes: Includes offset/digital printing, foil stamping, embossing, and coatings

- Custom Components: Inserts, closures, magnetic flaps, etc.

- Tooling Fees: Die-cut and mold setup charges

- Prototypes: Sampling fees, if applicable

- Freight & Delivery: Whether local or international, always include transit costs

- Storage & Handling: Warehousing and fulfillment charges

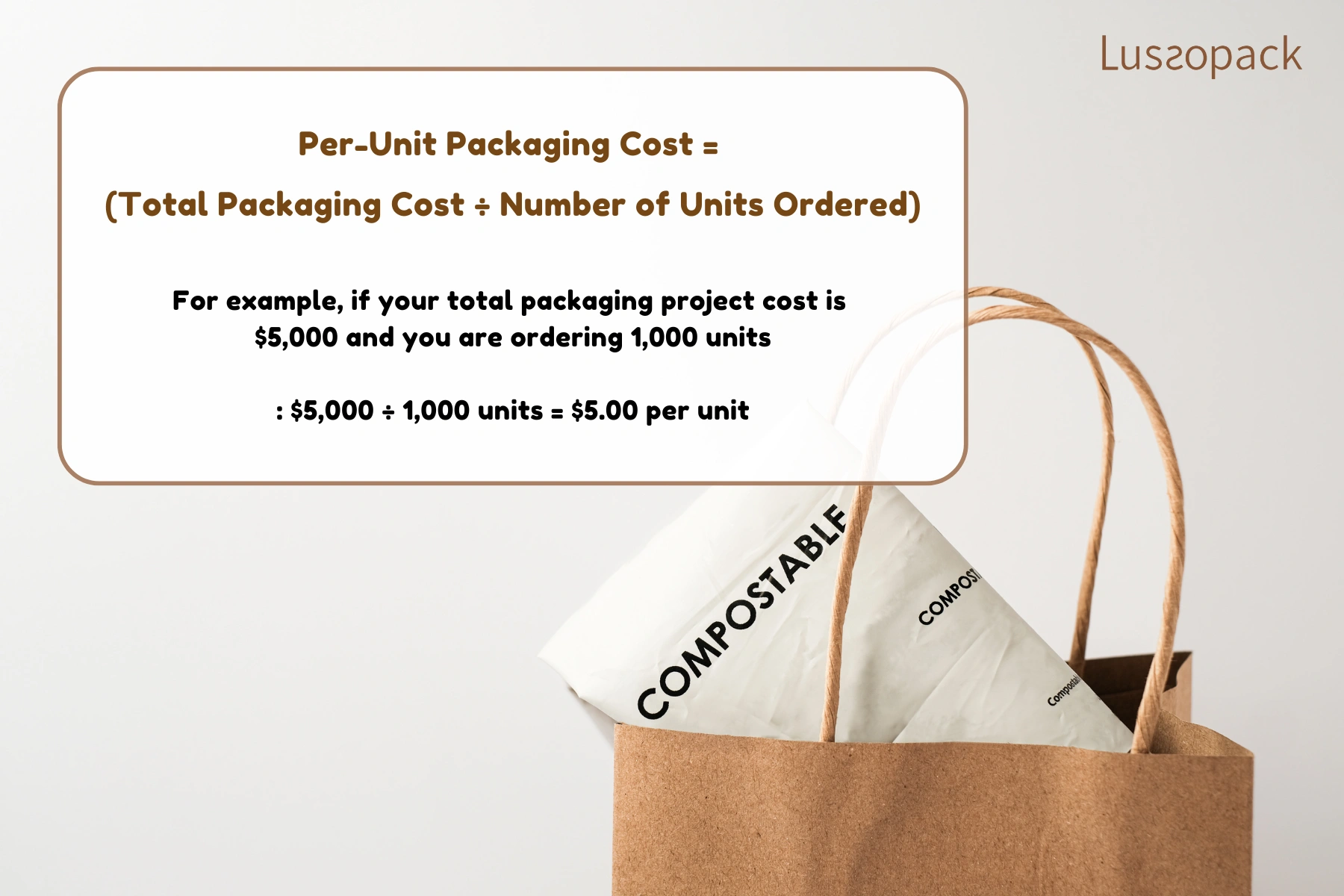

Step 2: Break Down Per-Unit Cost

Once you’ve outlined all cost elements—materials, design, tooling, shipping, and storage—calculate your per-unit cost by dividing the total project cost by the number of units ordered. This figure helps you understand your unit economics, which is critical for pricing your product, managing margins, and scaling responsibly. A clear per-unit cost also allows you to compare multiple packaging options and make cost-effective decisions without compromising quality.

- Formula:

Per-Unit Packaging Cost = (Total Packaging Cost ÷ Number of Units Ordered)

For example, if your total packaging project cost is $5,000 and you are ordering 1,000 units: $5,000 ÷ 1,000 units = $5.00 per unit

Step 3: Use a Packaging Cost Calculator

Many professional packaging suppliers offer access to an online packaging cost calculator. These tools allow you to input basic parameters such as box dimensions, material type, order volume, and finish preferences to generate an estimated price range. While not exact, these calculators provide a helpful baseline when you’re exploring options or building out early-stage budgets. They’re particularly useful for small businesses or new product lines where cost visibility is essential from the start.

Step 4: Include Unexpected Costs (Contingencies)

Always build flexibility into your budget. Unexpected costs can arise—from changes in material pricing and foreign exchange rates to urgent shipping needs or last-minute design adjustments. This is especially important for international orders, where customs duties, freight delays, or regulatory requirements may impact your final costs. Adding a contingency buffer of 10–15% ensures you’re prepared for real-world conditions without disrupting your production timeline or bottom line.

This formula offers a reliable foundation for calculating your packaging costs with clarity and precision, helping you make informed decisions, manage budgets effectively, and avoid unexpected expenses down the line. From affordable shipping boxes to fully customized luxury displays, packaging pricing spans a wide range. That’s why understanding how to calculate packaging cost is essential for any brand.

At Lussopack, packaging is treated as a craft—an expression of your brand’s character, quality, and purpose. Every detail, from the feel of the materials to the precision of the structure, is thoughtfully considered. We don’t believe in off-the-shelf solutions. Each box we create is built to suit the product it holds and the story it tells. Jewelry and watch brands come to us for packaging that speaks with quiet confidence. Refined, sustainable, and unmistakably bespoke, every piece is thoughtfully developed from the inside out. From initial sketches to final production, we provide hands-on support and deep industry knowledge to ensure your packaging reflects the same level of care and precision as the product it holds.

If you’re ready to create something that makes a lasting impression, our team is here to guide you. Contact us for tailored advice or explore our portfolio of handcrafted luxury packaging solutions.